AutomatedTrain

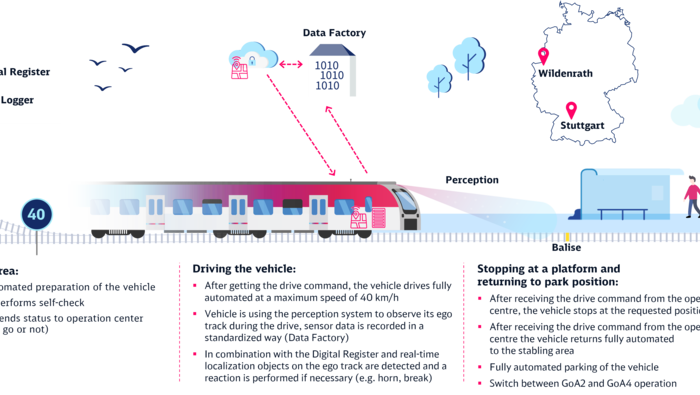

The "AutomatedTrain" cooperation project enables more flexible use of trains through automated preparation of the vehicle and fully automated, driverless train dispatching and parking functionality. Intelligent sensors enable the vehicles to detect their surroundings and react independently to obstacles – comparable to autonomous driving of cars on the road.

In the "AutomatedTrain" research and development project, DB InfraGO AG and eight other partners are testing the fully automated, driverless dispatching and stabling of trains as well as the automated preparation and shutdown of trains. Bringing together industry, rail transport companies, rail infrastructure operators and science, the project team forms a unique consortium from various sectors. The Federal Ministry for Economic Affairs and Climate Action is funding the project with around 42.6 million euros.

By 2026, a train from Siemens Mobility (Mireo) and a train from S-Bahn Stuttgart (Alstom BR 430) will be equipped with the relevant hardware and software. The Mireo train will cover the route from the siding area to the first station in the Wegberg-Wildenrath test center fully automatically and without a train driver. The train will brake automatically when obstacles are detected. The fully automated preparation and shutdown of the train is also being implemented and tested. In addition, Bosch's obstacle detection system is being tested in non-intrusiveness mode, i.e. in shadow mode, on the second train in the Stuttgart S-Bahn network.

The project focuses exclusively on fully automated, driverless driving (Grade of Automation 4 - GoA4). Details on the degrees of automation are explained here. As part of the vision of Digitale Schiene Deutschland, the development of GoA4 systems is based on ETCS Level 2.

Find out more about the project in the interview with project lead Susanne Gschwendtner:

Our partners

Funded by

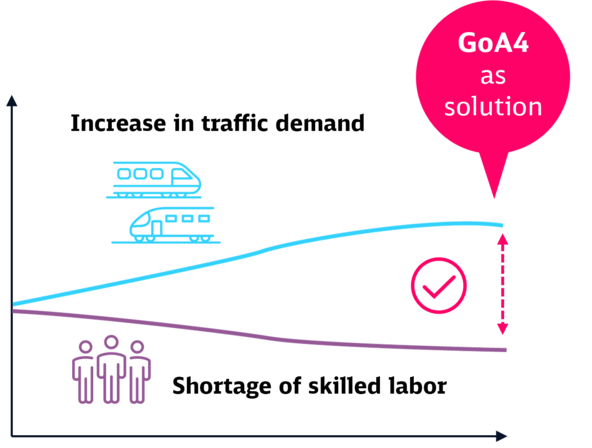

In future, rail transport is to play a central role in the decarbonization of transport and the achievement of the German government's climate targets and is therefore expected to take on a significantly larger volume of transport performance. This goal can only be achieved by significantly increasing the number of train journeys and thus the necessary increase in network capacity. The necessary increase in demand for train drivers (Tf) will be met by an already limited supply. In the future, there is the threat of a further gap due to the retirement of the baby boomers in their mid/late 20s from active service. Therefore, the most important operational advantage of fully automated driving and automated upgrading is the independence of vehicle deployment from personnel. This leads to greater flexibility - an important prerequisite for the planned increase in rail traffic. In addition, fully automated dispatching enables more effective deployment of personnel and thus greater operational stability, which is necessary in view of future demographic change. Against this background and in view of the enormous staff shortage, it is essential for Deutsche Bahn to press ahead with automation.

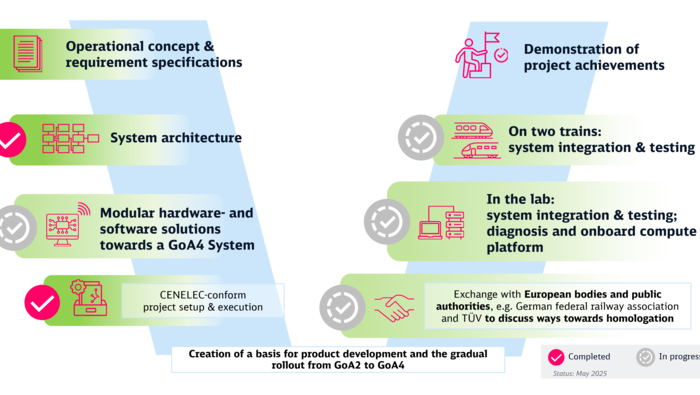

The aim of the "AutomatedTrain" project is to demonstrate the technical feasibility of fully automated, driverless driving for the use case of fully automated train dispatching and parking functionality.

Two prototypes will be equipped by 2026:

- The Mireo Smart train from Siemens Mobility will be used to develop and test the fully automated train preparation and shutdown process, including an automatic self-check of the vehicle. On a test site in Wildenrath the Mireo will then cover the route from the stabling area to the first platform fully automatedand without a train driver. If there are obstacles on the tracks, the vehicle brakes automatically.

- A second train of S-Bahn Stuttgart collects data in the operational railway environment for intelligent obstacle detection during test runs, without any intervention in the vehicle control system. The driver of the train therefore remains responsible for track safety in this project.

Both vehicles will be equipped with almost the same hardware, but with different software solutions for obstacle detection. This allows the recorded sensor data and the software's reactions to special incidents to be compared with each other.

The results of "AutomatedTrain" will be presented at InnoTrans - the international trade fair for rail and transport technology - in 2026.

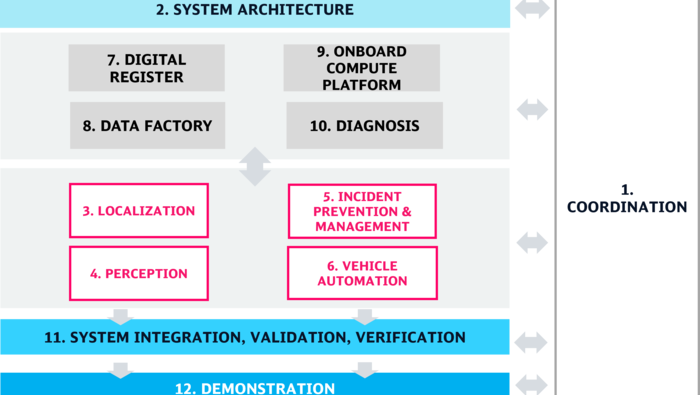

The "AutomatedTrain" project consists of twelve sub-projects. The following graphic represents the technical, specification-related and organizational sub-projects in which the necessary subsystems for future fully automated rail driving are being developed, specified and organized. Together with the project partners, a holistic solution approach is being developed.

The aim of the "AutomatedTrain" project is to develop a system architecture for fully automated driving in ATO GoA4 mode based on ETCS. This is to be implemented in accordance with the European Committee for Electrotechnical Standardization 5012X standards in a process-compliant manner with end-to-end traceability across the individual specification phases. The system architecture will then serve as a uniform reference for the development of the AutomatedTrain System for rail operators and industry and form the common basis for technology development.

Based on the operating concept and the system definition, the requirements for the system and the modular and open system architecture for a fully automated vehicle and the required infrastructure are derived. The functions - such as the reaction to an obstacle in the track, which is required for driverless driving (GoA4 - Grade of Automation 4) or the fully automated upgrading and downgrading ("raising and lowering") of the train - are then developed and implemented in two regional trains of different series. This is intended to provide a vehicle-independent functional verification of the core functionality "reaction to an obstacle on the track".

Before the systems are tested in a vehicle environment, each software release is tested in a special laboratory environment. This is followed by system integration and tests on the two trains. This allows the developed system architecture to be verified against the defined requirements and the system to be validated. In addition to the two prototypes, requirements for a functionally safe and high-performance train-side computer platform and diagnostics are developed, which are needed for future fully automated train driving.

During the development of the system architecture, particular attention is paid to the standardization and approval-compliant derivation of the requirements, test cases and interfaces in order to ensure that the results can be used for possible subsequent approval and European standardization after the project is completed.

The vehicle automation sub-project deals with the automation of all vehicle functions that are currently performed by train drivers. These vehicle functions include the preparation service, such as test runs or entering train data before the start of a drive. But they also include functions such as stopping and parking brakes, setting the direction of driving, driver manning and train parking. The automation of these vehicle functions is being developed and prototypically tested. The implementation is carried out on the Mireo Smart vehicle based on the selected use cases, e.g. the dispatching or parking of a train or the response to an incident prevention command (e.g. automatic braking).

The localization sub-project focuses on locating and evaluating the position of the train front to support the detection of obstacles on the track. The focus is on the localization of the track section, the train head in the course of the track and possible obstacles on the track. In addition, different approaches are being investigated and tested to determine the orientation of the trains. The focus here is on the environment detection sensors, in particular the camera for rail detection. Another task is the assignment of objects to mapped zones, such as platforms, open tracks, stabling areas, etc. This makes it possible to derive a differentiated response strategy to improve system availability. Essential data and information for this is provided by the digital register.

Perception plays a central role in the implementation of fully automated rail driving. A common set of sensors for perception and localization must therefore be identified, defined and qualified for use in rail vehicles. The sensors should have defined and freely available interfaces for measurement data recording, data processing and, if necessary, sensor fusion, and should be freely available on the market.

Furthermore, certifiable methods and algorithms are to be developed to detect and classify objects and obstacles in the recorded data. Infrastructure elements, such as tracks or catenary supports, are to be detect in order to be able to assign the objects to the train's route and determine the train's exact position.

Incident prevention and management

For driverless train operation, technical systems must monitor the route while the train is moving. Fully automated trains must be able to react independently to irregular situations and disruptions. Incident prevention and management is responsible for detecting and reacting to non-regular situations and is therefore a central component of fully automated driving.

As part of "AutomatedTrain", such an incident prevention system with intervention in the vehicle control system is being developed and tested. So fare, there is no approved, functionally safe scene composition of regular or irregular situations based on sensor-based environment perception and digital maps in the rail environment. A standardized situation evaluation and derivation of the train's reaction is being aimed in the project.

System integration, validation and verification

This sub-project includes the planning and implementation of system integration, validation and verification of the AutomatedTrain system. System integration is the integration of the individual subsystems into a superordinate, coherent system.

The integration is planned according to the use case in two different vehicles (BR 430 and Mireo) and a different system layout. The aim is to evaluate the system functions realized by the interaction of the subsystems. Before the systems are tested in a vehicle environment, each release is tested in advance in a laboratory environment.

In order to prepare the two vehicles for the respective later tests with the developed systems, it is also necessary to adapt mechanic and electrical interfaces in the vehicles - from the conception to the implementation of vehicle modifications and the initial installation of the AutomatedTrain system in the vehicles.

Sensor-based perception and localization systems, such as those tested in "AutomatedTrain", require knowledge of objects along the route as well as information about the exact, three-dimensional course of the track (3D centerlines of track) in order to be able to determine a clear position. This data comes from the Digital Register, which consolidates and aggregates topology and topography data of the rail infrastructure. The Digital Register contains infrastructure data on points, balises etc. as well as a digital location of 3D landmarks such as buildings, platforms and signs.

The contents of the Digital Register are contained in an object catalog, which is constantly being further developed through its use on real test routes. Objects are scanned as point clouds and converted into digital reference objects. The partners in the sub-project are developing technological approaches for automated object labeling (identification and marking of the object) and the automatic detecting of static objects for the creation of the Digital Register.

Data Factory

Fully automated driving generates very large amounts of data due to sensor-based environment perception and localization. The focus of the Data Factory sub-project is the systematic recording, storage and processing of sensor data in the rail environment in order to generate high-quality multi-sensor data sets and a synchronized multi-sensor data pool. To achieve this, collected data is recorded using data recorders in the vehicle, encrypted and transferred to a central data center for storage and processing.

In "AutomatedTrain", prototypes are being developed for a touchpoint and a data logger that enable the data flow of large amounts of recorded sensor data from the train to the data center outside the train. A touchpoint will connect wirelessly to a train within range and download the large amount of sensor data that the train has collected during its journey. The touchpoint and data logger are connected to the data center as a data network for data exchange. Great care is taken to ensure that all collected data is processed and stored in compliance with the GDPR. The collection and storage of test data is only used to verify and validate the system.

Diagnosis

The onboard systems for fully automated driving require advanced concepts for operational monitoring and automated fault management. As part of "AutomatedTrain", a manufacturer-independent onboard diagnosis concept is therefore being developed for the use case of sensors for environment detection and implemented as a prototype in the laboratory. In addition, the transferability to other use cases, such as the localization function, will be taken into account so that the concept can be extended to all GoA4 onboard functions and implemented on the train.

For fully automated driving in GoA4, in particular for the "perception" and "incident prevention management" functions, computer systems with an optimized hardware and software basis are required on the train side. Such onboard compute platforms, which would be certified and permitted for rail operations, are currently not available on the market. (Partial) solutions already exist in other sectors, such as the automotive industry. However, their transfer for driverless operation in open rail systems must be examined and evaluated in detail. The rapid development of technology and its sustainable and economic integration into the rail sector represents a major challenge.

Therefore, the train-side compute platform with requirements of the railroad system is defined on the one hand and the feasibility of the technology transfer is investigated on the other.

Vehicle Data Logger

The Vehicle Data Logger is a powerful and rail-certified system designed to capture, process, and transmit large volumes of sensor data. It ensures seamless data flow from train to ground, enabling efficient storage and analysis for automated rail operations.

Key Features:

-

Modular Hardware and Software Architecture to applicated different use cases in railway environment.

-

High-capacity data recording – Captures 120 TB of sensor data.

-

Toolless and Hot Plug SSD Disk Exchange

-

Robust computing power – Handles complex processing tasks efficiently.

-

Wireless data transmission – Secure WiFi transfer from train to trackside infrastructure.

-

Certified rail-grade hardware – Designed for reliable operation in demanding railway environments according to CE, EN45545, EN 50155, EN 50121, REACH, RoHS & EMV06.

-

Remote maintenance access – Enables system updates and diagnostics via mobile networks for smart operational management.

The Vehicle Data Logger is designed to record ROS2 sensor and functional data streams. With a cloud connection monitoring and health status information are available for a smart operational management. The Vehicle Data Logger has a modular architecture in both hardware and software and can therefore be applicated for different uses cases in rail environments.

For further details please contact us.

Data Sets

Our Open and GoA4 Data Sets provide high-quality, multimodal sensor data with detailed annotations for research and development in rail automation. Whether you need open-access datasets or exclusive licensed data for advanced applications, we offer structured, high-precision sensor recordings for various use cases.

Open Data Sets:

-

Available in collaboration with Federal Railway Authority (EBA) / German Center for Rail Traffic Research (DZSF) as part of the Project OSDaR23.

-

First freely accessible multimodal sensor dataset with annotations.

-

Ideal for academic research and public-sector innovation projects.

GoA4 Datasets:

-

Extensive multimodal sensor datasets with structured annotations.

-

Available for licensed use in automated rail system development.

-

Supports data-driven innovation in railway operations.

-

The senor date consists of image/video data (also infrared), radar, Lidar and GNSS/IMU data.

-

The annotated object classes are: person, personal_item, pram, crowd, train wagons, bicycles, group of bicycles, motorcycle, road vehicle, scooter, animal, group of animals, wheelchair, drag shoe, track, switch, catenary pole, signal pole, signal, signal bridge, buffer stop, flame, smoke.

For further details please contact us.

From requirement to realization on two different series in three years

Videos

AutomatedTrain: Retrofit of the Baureihe 430

At the Alstom factory, we spend a day observing the retrofit of the Stuttgart S-Bahn's 430 series train. One of the two test vehicles in the AutomatedTrain project was equipped with sensors at the front of the train for environmental perception and antennas on the roof for optimal data exchange, among other things.

AutomatedTrain: Digitale Schiene Deutschland develops and tests automated preparation and shutdown of trains

Digitale Schiene Deutschland accompanied two train drivers as they carried out their preparatory shutdown of the train. In the video, they explain which work steps are still carried out manually today and could be eliminated in the future.

Funding award handed over by the BMWK for the AutomatedTrain development project

Development project AutomatedTrain: Digitale Schiene Deutschland and industry receive funding from the Federal Ministry for Economic Affairs and Climate Action (BMWK) for testing fully automated train driving.

Interview with AutomatedTrain project lead Susanne Gschwendtner.

Susanne Gschwendtner, Project Lead of AutomatedTrain (Digitale Schiene Deutschland), talks in an interview about why the rail system of the future needs fully automated, driverless driving and explains the goals and benefits of the project.

Publications

We are constantly writing articles in cooperation with trade magazins, which are unfortunately only published in German. If you are interested, you can find them here.

- AutomatedTrain: Digitale Schiene Deutschland develops and tests automated preparation and shutdown of trains

- Fully automated, driverless driving: A response to the shortage of skilled labour in the rail industry

- AutomatedTrain: Project Lead Susanne Gschwendtner provides exciting insights into the future of rail transport

- Digitale Schiene Deutschland and industry receive funding to test fully automated train operation