Automatic Train Operation (ATO)

The Guarantee for a Particularly Efficient Traffic Flow

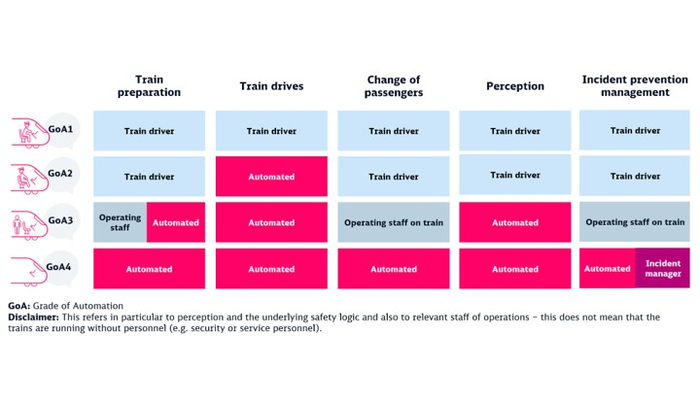

Automated vehicle systems are an essential prerequisite for highly and fully automated driving on the railways. They can be regarded as an autopilot for train traffic. The technology implements predefined instructions for accelerating and braking the train. The reaction times between transmission and implementation of the driving commands are significantly shorter and less subject to fluctuations than with manual control. Automatically operated light rail vehicles are currently still far ahead of cars. Automatic trains are already in operation in more than three dozen cities around the world, including Barcelona, Copenhagen and Paris. In Nuremberg, too, automatic subways have been in operation since 2008. In these systems, however, the rail network is not accessible from the outside. Automated vehicle systems will also be used in the so-called "mainline" sector (regional, long-distance and freight services) in the coming years. Here, the ATO technology must work smoothly with the infrastructure (ETCS - European Train Control System). According to the principle of "ATO over ETCS", the advantages of ETCS, automatic data transmission instead of light signals, are used to enable vehicle automation. There are four levels of automation.

Advantages of Vehicle Automation at a Glance

For highly automated driving in automation level GoA2, the train driver purely observes the route and only intervenes in the event of irregularities. In addition to the automation of the driving functions, this requires reliable infrastructure data from the "Digital Register" as well as high-performance (mobile telephony) communication between the vehicle and the infrastructure, e.g. for the exchange of closely timed (driving) instructions.

At the highest level of automation GoA4 - driverless driving - the train also takes over the environment and object recognition by means of sensors and requires an AI-based incident management. The necessary transmission of image and sensor data to e.g. an AI-based incident management system significantly increases the requirements for connectivity and makes high-performance mobile telephony based on FRMCS/5G necessary. For driverless driving in the GoA4 stage, further driving functions such as fitting and un-fitting, horns, etc. must also be automated. These functions, among others, are being automated in the development project AutomatedTrain of the Digitale Schiene Deutschland.

The Advantages at a Glance

Speed specifications are precisely adhered to through automated vehicle systems. Trains run more punctually and train operations are stabilised. This increases capacity and contributes to better operational quality and thus also to higher efficiency of the railway system. Optimised acceleration and braking also significantly reduces energy consumption and not only decreases wear, but also reduces maintenance costs. Furthermore, the technology enables new, more flexible operating concepts.

The Technology in Use

As the first pilot project of the Digitale Schiene Deutschland, the Digital S-Bahn Hamburg 2018-2021 project was implemented. There, highly automated driving based on the European Train Control System (ETCS) was used for the first time in Germany. Thanks to vehicle automation, the train driver only intervened in the event of malfunctions or irregularities - the vehicle started, accelerated, braked and stopped by itself. Since autumn 2022, four trains of the S21 line in Hamburg have been running in highly automated passenger service. In the Digital Node Stuttgart, a railway node will be completely converted to automatic railway operation in the automation level GoA2 for the first time. By the mid-2020s, more than 400 vehicles, distributed over five series, will be equipped accordingly and the trackside implementation has also started. The first step is the "AutomatedTrain" project. For this purpose, two regional trains will be equipped with state-of-the-art sensors by 2026, which will then be used for fully automated provisioning and stabling.