Stuttgart digital node: the first digitally controlled rail node

Germany's first digitalised rail hub for all train categories is being built in the Stuttgart metropolitan area

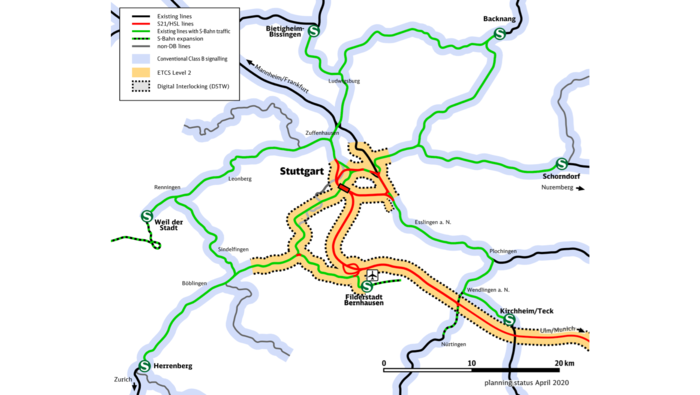

More reliable, more punctual, more efficient: the Stuttgart digital node sets new standards in rail transport. In the first stage, around 125kms of track will be equipped with new digital signalling system technology by 2025 – the rest of the area will follow and be completed by 2030. At the same time, around 500 vehicles will be equipped with digital technology. Step by step, we are installing new technology and successively optimising it so that more trains can run with fewer delays and Digital Rail for Germany can continue to gain momentum.

Click here for the BMVI press release.

The advantages at a glance

- Maximum performance on the particularly heavily loaded S-Bahn main line.

- In Stuttgart's new main station, a train can run every five minutes on each of the eight platform tracks in a high-performance operation. An average train sequence of two minutes is possible on each of the eight adjoining tracks.

- The experience gained in Stuttgart can be used for the planned digitisation of the rest of the network.

The technology comes into use

For the first time, we are equipping a major German railway junction with a digital interlocking system , the European Train Control System (ETCS), the integrated control and operating system, (iLBS:integrierte Leit- und Bediensystem), and other technologies based on it, such as automated train operation with driver (ATO GoA 2):

- Digital interlockings (DSTW: Digitale Stellwerke) form the basis of digitalisation. A highly secure computer system is connected to external elements, like sensors and points, via encrypted data connections. Like any modern interlocking, a DSTW ensures that trains only enter free track sections and that points are locked in the correct position. In Stuttgart, a DSTW is initially being built to control approximately 125kms of track.

- The ETCS is a uniform safety system for European cross-border traffic. Train and track continuously exchange location and speed data en route, via an encrypted radio link – initially via the railway's own existing mobile radio system (GSM-R). Instead of guiding trains via a simple red-yellow-green scheme of light signals, the ETCS on-board computer dynamically calculates, at any time, the free path in front of the train and permitted speed. In this way, trains can follow each other much more closely and precisely than with conventional control and safety technology. Initially, ETCS Level 2 is planned. The further development of Hybrid Level 3 is already being prepared by pre-equipping the vehicles with a system for monitoring train integrity.

- ATO is used in the Stuttgart digital node in automation Level 2 (GoA 2). The system works like remote-controlled cruise control: the track tells the train when it should be at which location. The onboard unit regulates the speed accordingly. In the event of a delay, the train drives at the maximum permissible speed, and during scheduled operations, it drives at the most energy-efficient speed. At platforms, ATO enables a high-precision stop. This avoids delays and shortens the distance between two trains. A driver is also on board to monitor the journey and intervene if necessary.

To bring this showcase project onto the rails, €462.5 million will be invested in the track technology by 2025. Up to €200 million more will be available to equip the vehicles. Initially, public mobile radio (4G/5G) will be used for ATO. By 2030, both ETCS and ATO will run via the new 5G-based FRMCS.

Further information about this project:

- Article in "Signal & Draht" | FRMCS equipment of 463 multiple units for the Stuttgart Digital Node | 05/23

- Article in "Signal & Draht" | Experience gained from track field networking at the Stuttgart Digital Node (part 1) | 04/23

- Article in "Signal & Draht" | Innovative cooperation for the vehicle equipment

at Stuttgart Digital Node | 09/22 - Article in "Deine Bahn" | ETCS Level 2 ohne "Signale" in einem großen Knoten | 03/22

- Article in "Eisenbahn Ingenieur" | Quo vadis Digitale Leit- und Sicherungstechnik? | 11/21

- Article in "Eisenbahn Ingenieur" | Fahrzeugnachrüstung für den Digitalen Knoten Stuttgart | 09/21

- Article in "Deine Bahn" | Digitaler Knoten Stuttgart: Digitalisierung ist kein Selbstzweck | 03/21