Digital signalling system

For improved capacity and punctuality in rail transport

The Federal Government's goal is that, by 2030, twice as many passengers, and significantly more freight traffic will be transported by environmentally friendly rail. To achieve these, Digitale Schiene Deutschland is already building the most essential foundations.

DB Netz AG currently operates around 2,500 interlockings. However, there are many different types of these – from mechanical levers going back to the days from emperor’s times to modern digital ones (DSTW: Digitaler Stellwerke).

To increase the reliability, quality and cost effectiveness of control and safety technology, we are replacing old interlockings types and those that are non-European Train Control System (ETCS)-compatible. In many cases, the old electric interlockings are ETCS-compatible and can therefore be used for the rollout as long as they’re still within their service life. As an integrative system with standardised interfaces, the DSTW – together with the uniform integrated command and control system (iLBS: integrierte Leit- und Bediensystem) – will become the heart of digital signaling system (DLST: Digital Leit- und Sicherungstechnik).

In addition to DSTW, the rollout of ETCS within the framework of DLST is also of great importance. In a Europe that’s growing ever closer, both economically and politically, it is the basic prerequisite for seamless cross-border rail traffic.

First digital signal box for long-distance railway in operation in Warnemünde

What is digital control and safety technology (DLST: Digital Leite- und Sicherungstechnik)?

Our goal is to bring rail transport into the future by seizing all new opportunities presented to us by digitalisation.

DLST will generate many advantages for railway infrastructure. The many different interlocking technologies in use today will be replaced across the board, removing any manufacturer-related differences. This way, we simplify and improve operation, maintenance and qualification.

Advantages of DLST at a glance:

- More functionality

- Improved punctuality

- Higher availability

With the new generation of control and safety technology, DLST, DB Netz AG's Technology and Facilities Management team will, in the coming years, equip the network with a uniform platform for the first time. This will enable more economical operations.

DLST is made up of:

- Digital interlockings (DSTW: Digitaler Stellwerke)

- European Train Control System (ETCS)

- Integrated comand and control system (iLBS: integrierte Leit- und Bediensystem)

Furthermore, the digital control and safety technology builds on supporting systems and further development projects, such as:

- Railway IP network (bbIP: Bahnbetriebliches IP-Netz)

- IT security (ITsec)

The digital interlocking (DSTW) – a new generation of interlocking technology

An important building block for the railway of the future

The digital interlockings (DSTW: Digitale Stellwerk) is a further development of the electronic interlockings (ESTW: Elektronisches Stellwerk) and, as part of the digital signaling system (DLST: Digital Leite- und Sicherungstechnik), is controlled via a new operating system.

DSTW will replace the many different types of interlockings , of varied designs and generations, with DLST. In contrast to an ESTW, a DSTW transmits the control commands digitally, via fibre-optic cable, to points and signals.

The advantages:

- Greater distance

- Standardised interfaces

- Condition-based maintenance

- Separation of energy and data

- Improved diagnostic capability

As the standardised interfaces of the DSTW are open and IP-based, components from different manufacturers can be interconnected to form an overall system. This way, DB Netz AG facilitates competition for diverse technical solutions from individual manufacturers.

This leads to increased quality and efficiency of control and safety technology – an essential and important contribution to Digitale Schiene Deutschland.

Digital Rail Test Field in the Ore Mountains

Nationwide rollout of new interlocking technology

To roll out a new technology, it must of course be developed, tested and approved. Digital interlockings will be rolled out in four phases:

- Initial test implementation (Referenzimplementierungen)

- Broader test implementations (Vorserie)

- Industry projects and starter package (Industrialisierungsprojekte sowie das Starterpaket)

- Industrial rollout (Industrieller Flächen-Rollout)

Individual interfaces have already been realised and tested in phase 1. The following projects are now in phase 2, in which the interfaces are built and tested:

- Warnemünde

- Meitingen-Mertingen

- Harz-Weser network

- Koblenz-Trier

In phase 3, we test planning principles and transfer them onto the regulations. In phase 4, we can put digital interlockings with European Train Control System (ETCS) technology into operation and start introducing them throughout Germany.

Already more capacity in the rail network

The European Train Control System (ETCS) and digital interlockings are the core systems of digital control and safety technology – and increased capacity in the rail network. Ultimately, 280 digital interlockings will control operations on Germany's rail network. The digital interlocking in Annaberg-Buchholz has already been in operation since 2018, and the second one in Warnemünde has been in operation since autumn 2019. Three more will follow before 2023.

Europe's first digital interlocking system – from Annaberg-Buchholz to the German rail network

An Ore Mountain town is making railway history: Annaberg-Buchholz has kicked off the new age of digital interlocking technology. Points and signals were set digitally – and reliably – here with a system from Siemens.

The integrated command and control system (iLBS) – the operating system of the future

Developed as part of the project Design-integrated Operator Station (DiB)

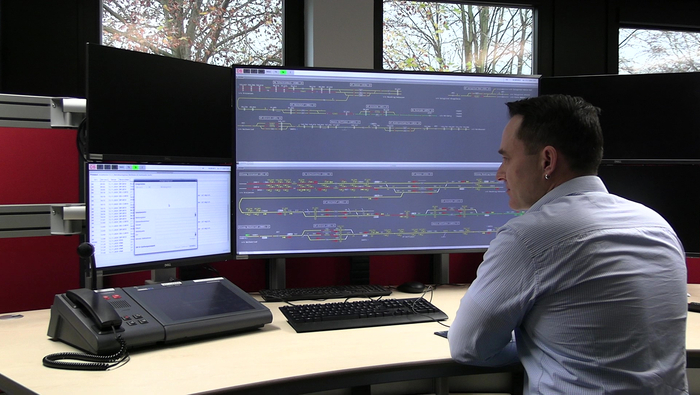

With the integrated command and control system (iLBS: integrierte Leit- und Bediensystem), the operating system of the future is being developed. The most important ‘man-machine’ interface for the future control and monitoring of all traffic on the routes of DB Netz AG is being created.

The iLBS bundles together all applications required for operation, and standardises operations. By means of a newly developed interface to the electric/digital interlocking (SCI-CC_LST), 100% standardisation is ensured so the interlocking behave the same way, whoever the manufacturer, and operating differences are eliminated. This harmonisation significantly simplifies operation, training and maintenance.

In the future system, safety-relevant aspects will be shifted from the operating to signalling level. On one hand, this makes hardware-neutral development possible. On the other, commercially available hardware components can be used, which will reduce costs and dramatically simplify approval processes in the future.

The development of the iLBS is accompanied by the development of a new integrated operator workstation (iBP: integrierten Bedienplatzes). The iBP marks the beginning of a new generation of workstations with a standardised, daylight-compatible user interface and user-friendly, intuitive and future-oriented operator guidance system.

iLBS and iBP – the advantages:

- Uniform, flexible, manufacturer-independent operation

- Efficient management

- Manufacturer- and hardware-neutral developments

- Use of commercially available components

- Flexible assignment of interlockings to operating locations

- Easier integration and exchange of systems in mobile operation

- Daylight workplaces and improvement of working conditions

- Intuitive user guidance for all applications required for operation

With the integrated command and control system and the new integrated operating stations, the Design-integrated Operator Workstation (DiB: Design integrierter Bedienplatz) makes another important contribution to the reliability, efficiency and digitalisation of the railway system. Together with developments on ETCS and DSTW, the new operating system establishes an interaction that will allow the future digital railway system to develop to its full potential.

DSTW phase 2 projects and ESTW are equipped with iLBS

The realisation of the integrated control and operating system (iLBS: integrierte Leit- und Bediensystem) will take place in several releases.

In Release 1, the electric or digital interlocking operating functionalities are initially implemented and extended by the functionalities of the European Train Control System (ETCS). The integration of the telecoms message display and dispatching systems will be carried out in further releases.

The first iLBS was successfully put into operation in November 2020. With a new iBP in Göttingen, the electronic interlocking (ESTW: Electronisches Stellwerk) Seesen is operated from the regional control centre. With this commissioning, the complete standardisation of the SCI-CC_LST interface has been implemented.

The next iLBS commissioning will take place in 2021 as part of further reference projects in the area of ESTW Göttingen, Seesen Harz-Weser-Netz (HWN) and Kreiensen. In this step, cross-manufacturer operations will be realised.

These projects will follow:

- Koblenz-Trier – in service 2024 (phase 2 project, new DSTW construction)

- Harz-Weser-Netz – in service 2026 (phase 2 project, new DSTW construction)

- Kreiensen II – in service 2024 (extension phase 1, new ESTW construction)

- Düsseldorf – in service 2026 (iBS control centre, new ESTW construction)

- Stuttgart-Ulm – in service 2025 (Digitale Schiene Deutschland starter package, new DSTW, ETCS construction)