Digital Twin for Fully Automated Rail Operations: Dr. Sebastian Skibinski on AI Training with Virtual Scenarios

To enable trains to run safely and fully autonomously on open networks, it takes more than just powerful sensors – what’s also crucial is a purposefully trained artificial intelligence (AI). But how can AI be prepared for disruptions and emergency situations for which hardly any real-world data exists? As part of the sector initiative Digitale Schiene Deutschland, DB InfraGO has developed a digital twin of railway operations: a virtual environment where critical scenarios can be comprehensively simulated and AI systems trained. This work has provided important impetus for the industry and laid the foundation for railway operators to be able to order such systems in the future.

In this interview, Dr. Sebastian Skibinski, Head of Disruption and Emergency Management for Automated Driving, explains how the digital twin works, what challenges are involved, and why it is a key building block on the path to fully automated train operation.

Sebastian, fully automated rail operations require comprehensive perception, decision-making and action systems. What exactly are these?

The foundation for fully automated, driverless operation (ATO GoA4) essentially consists of three steps: perceiving the environment (Sense), evaluating situations (Think), and finally initiating necessary measures (Act) – such as an acoustic warning or an emergency brake. These three steps are essential for being able to respond safely even in unforeseen situations.

What specific challenges and opportunities do you see in developing a digital twin for fully automated driving in an open rail system compared to closed systems?

Fully automated driving in an open system is significantly more complex than in a closed system such as a metro. For the digital twin, this means that far more scenarios must be realistically recreated and simulated. With every additional degree of freedom, the number of possible scenarios increases exponentially. In short: the more complex the real environment and the functions to be replicated, the more elaborate and extensive the simulation needs to be.

How do digital twins help simulate critical scenarios for automated train operations, and what are their main advantages over traditional testing methods?

Recreating 50 scenarios on a real test track takes about two weeks. In the simulation, a single scenario currently takes about five minutes, so around four hours for the same number of scenarios. This already gives us an efficiency factor of 20. Put differently: in the same time we can simulate 1,000 scenarios instead of 50 – and since hardware and software don’t need breaks, up to 4,000 scenarios are possible. Another advantage: we can scale the simulation as needed by adding more hardware. At the moment, for example, we’re running it on four servers each equipped with eight powerful ray tracing GPUs.

What role does artificial intelligence play in this?

Artificial intelligence is central to meeting the high requirements for tasks such as image recognition or behavior prediction in automated rail operations. What seems almost effortless for humans – such as recognizing obstacles even under difficult visibility conditions caused by snow, rain, leaves, or shadows – is highly complex for technical systems. Traditional methods quickly reach their limits here. Machine learning methods offer great advantages, but they require very large amounts of training data – which are not sufficiently available in real life. Simulation allows us to meet this data need in a resource-efficient way.

What features and tasks does the digital twin of the rail network have?

We’re accurately replicating the real rail networks of Hamburg, Berlin and, in the future, also Stuttgart in the digital twin. A central part also includes modeling the two trains from the cooperation project AutomatedTrain*, where DB InfraGO is the consortium leader. In this project, we’re testing fully automated, driverless dispatching and stabling runs as well as automated preparation and shutdown of trains. These digital train models also include their complex sensor setups, which are critical for environment perception. Beyond that, we simulate both regular and non-regular operational scenarios – based on a universal description language that can be read and unambiguously interpreted by both humans and machines. We first describe the scenarios using parameters, which are then automatically specified further. This makes it possible to efficiently represent and test the enormous variety of potential situations in rail operations.

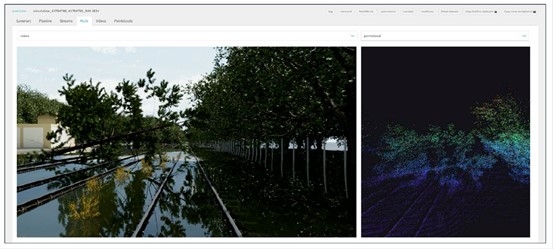

A precise model of real railway lines and the automated simulation of relevant operational scenarios – how does this work in practice?

For this, we’ve set up a complex simulation toolchain in which the 3D simulation and development platform NVIDIA Omniverse plays a central role, supplemented by many other tools. This makes it possible to simulate very diverse scenarios, such as deliberately flooding certain sections of track to test the system’s response (see illustration).

Where is the digital twin used? And what’s next?

The digital twin is currently used extensively in the AutomatedTrain project. It mainly helps us cover the necessary range of non-regular scenarios that, for safety reasons, cannot be recreated on a test track in real life. At present, we’re examining how we can turn this simulation into a qualified series product. After the project is completed, our industry partners can start their series development directly based on the insights gained.

Detailed information about the digital twin can be found in an article published in June 2025 in the journal ETR – Eisenbahntechnische Rundschau.

Link to article (in German)

*AutomatedTrain is funded by the Federal Republic of Germany and the European Union. The funding providers are the Federal Ministry for Economic Affairs and Energy based on a resolution of the German Bundestag, as well as the European Union.