Railroad Operating Field Darmstadt: An Indispensable Simulation Platform for Digital Rail Technologies in Germany

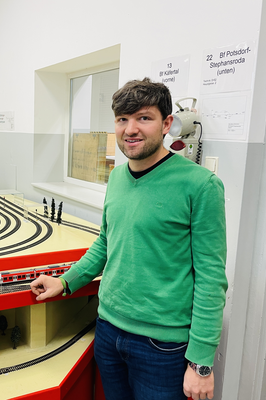

January 2025 - Railway operating fields in Germany have a long-standing tradition and maintain significant relevance in the digital age. A key application area includes simulating innovations within a controlled laboratory environment prior to conducting expensive field tests on actual railways (see also article). These simulation facilities enable the recreation of various rail operation scenarios, allowing observation and analysis of new innovations' impacts on the overall system from a comprehensive perspective. One of the most renowned facilities is the Darmstadt Railway Operating Field (Eisenbahnbetriebsfeld Darmstadt EBD), utilized by Digitale Schiene Deutschland for early testing and further development of innovative technologies. Dr.-Ing. Frederik Düpmeier, a staff member in the system development department for integrated control and safety technology and former head of development at TU Darmstadt at EBD, explains the significance of EBD for current development projects.

The Eisenbahnbetriebsfeld Darmstadt (EBD) was established in 2006 as a cooperative project between DB Training, the Technical University of Darmstadt, and “Akademischen Arbeitskreis Schienenverkehr e. V.” It primarily serves the training and further education of various target groups, such as train dispatchers. The training is notably practical, as participants test realistic operating situations on a digitally controlled model railway system.

“Focusing on Digitale Schiene Deutschland technologies, research and development are paramount,” says Frederik Düpmeier.

EBD collaborates closely with various educational, research, and industry partners. This cooperation facilitates knowledge and experience exchange and promotes joint solutions to rail transport challenges, such as increasing capacity and reliability within the existing rail system.

International partnerships with foreign railroad companies and regular workshops with future users of new railroad technologies also contribute to continued development.

Technical Equipment and Infrastructure

The EBD features a digitally controlled model railway layout that includes a wide range of vehicles and classic field elements such as points, signals, and level crossings. The H0 layout, at a model scale of 1:87, represents around 135 kilometers of track with a length scale of 1:250. This smaller scale allows the simulation of realistic travel times between operating points.

The model railway layout is modular and can be controlled in various configurations using replica electronic interlockings or older types of interlockings (mechanical, electromechanical, and relay interlockings). A driving simulator complements the hardware setup.

The software serves as the EBD's core. It comprises numerous independent applications with standardized interfaces wherever possible, including various interlocking simulations, dispatching systems, passenger information systems, and a timetable editor. The modular structure of the EBD allows for continuous hardware and software adaptation and expansion, as well as the replacement of individual components with innovative new systems integrated into the existing framework.

Research and Development at Eisenbahnbetriebsfeld Darmstadt

EBD facilitates the early testing of innovations through "pretotypes," early experimental models evolving into actual prototypes. "Sustainable improvements can be achieved through user feedback and the ability to quickly modify the pretotype based on feedback," states Düpmeier. EBD analyzes the operational impacts of innovations in a system context and provides a platform for exchanging research insights by demonstrating new technologies and highlighting their benefits. This process allows for evaluating new technologies, assessing their benefits, and fostering an understanding of complex rail operation processes.

Digitale Schiene Deutschland actively participates in various EBD projects. These include testing new rail service regulations for digital rail operations (Directive 400) and demonstrating the Capacity and Traffic Management System (CTMS). CTMS optimizes planning and scheduling processes to enhance capacity utilization and traffic management on the rail network. The system uses AI and machine learning technologies for real-time train traffic control and coordination, aiming to enable more efficient infrastructure use and minimize delays.

"CTMS optimizes operations based on the current situation, adjusting the timetable in case of disruptions," explains Düpmeier.

Another innovative technology to be demonstrated and evaluated at EBD in 2025 is the Advanced Protection System (APS), a core part of the Advanced Digital Infrastructure (ADI). The APS, designed for future infrastructure-based safety, departs from fixed predefined routes with defined spatial lengths (blocks and routes) to dynamically reserving only the necessary track area for the minimum possible time, based on each train's characteristics. This approach allows trains to run at shorter intervals, enabling a denser train sequence on the existing rail network without additional infrastructure construction. APS will assume key responsibilities of existing signal boxes and ETCS route control centers, with ETCS on-board systems, also simulated at EBD, ensuring train movement compliance.

Challenges at EBD

One primary challenge is maintaining the model train system, which must endure intensive, continuous use.

“Every model train enthusiast knows that components are not designed for constant use. Hence, regular maintenance and delicate element care are necessary, occasionally leading to technical issues,” says Düpmeier.

Additionally, finding available slots at EBD can be difficult, given its near-constant use.

In the coming years, EBD's test and simulation concepts will evolve to meet modern research and training requirements. Focus areas include greater integration of the driving simulator and continuous optimization of digital planning and data provision, tested on the model railroad. Efforts to enhance scientific communication and evaluate new technologies are also underway.

“For Digitale Schiene Deutschland (DSD), the Darmstadt railroad operating field is a valuable research site for early-stage, limited-scale testing of technologies required for digital rail operations,” summarizes Düpmeier. By combining practical training with innovative research, EBD significantly contributes to the efficiency and future viability of rail transport.